A comprehensive guide to scaffolding connections and their use

In civil engineering, construction, industrial and refinery projects, scaffolding plays a vital role in providing safe access to heights and carrying out construction or repair operations. One of the main elements in the erection of these temporary structures is scaffolding connections, which are responsible for connecting, maintaining and strengthening the scaffolding components.

In this article, we will examine the types of scaffolding connections, their characteristics, applications and safety tips related to them.

What are scaffolding connections?

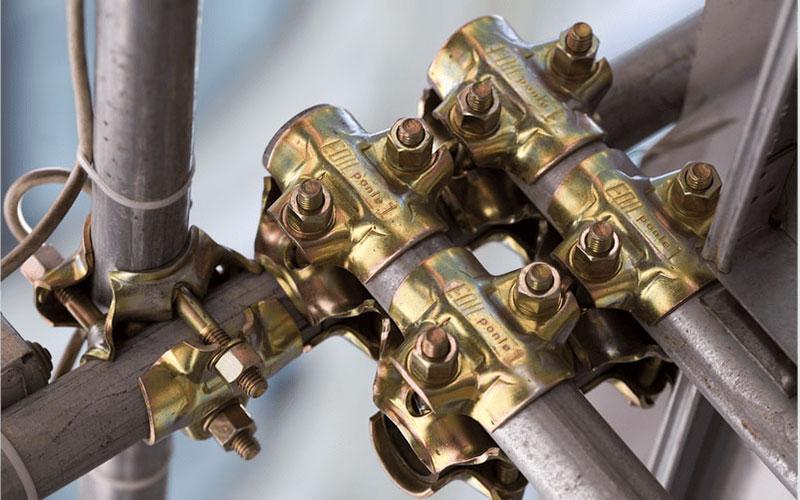

Scaffolding connections or “scaffolding clamps” are metal parts designed to connect scaffolding tubes to each other. These clamps play a key role in forming a stable, reliable and safe scaffolding structure. The quality, type and correct installation of these connections will have a direct impact on the safety of users and the strength of the scaffolding structure.

Types of scaffolding connections

1. Double-screw clamp (upright)

For vertical connection of scaffolding pipes

Widely used in perpendicular intersections

High mechanical resistance

2. Swivel clamp (rotary)

Connecting two pipes at a desired angle

Suitable for structures with irregular shapes

Flexible in design and execution

3. Core clamp (Japanese clamp or pipe connector)

For longitudinal connection of two pipes in line

To increase the length of the scaffolding

Easy and strong installation

4. Single-screw clamp (iron clamp or tulip)

Suitable for light and temporary connection

Light weight and high installation speed

Economical option for small projects

5. Hammer clamp (percussion)

Quick installation with just a hammer blow

No need for screwing tools

Suitable for high speed installation and dismantling

Standard scaffolding connection features

Made of galvanized steel or durable cast iron

Resistant Against rust and environmental conditions

Has quality certificates (EN74, BS1139, etc.)

Designed to withstand axial and lateral loads

Can be used repeatedly in various projects

Applications of scaffolding joints

High-rise construction projects

Industrial and petrochemical workshops

Urban and infrastructure projects

Execution of building facades and facade construction

Repair of historical buildings and special structures

Safety tips for using scaffolding joints

Check the physical and structural health of each joint before installation

Use a special scaffolding wrench to tighten the screws

Follow installation and loading standards

Do not use damaged or rusty joints

Train executives for correct and safe installation

Conclusion

Scaffolding joints play a fundamental role in the structure of scaffolding. Choosing the right type of connection for the project conditions, using standard equipment, and installing it properly will ensure the safety of personnel and the success of the project. A proper understanding of these types of connections helps engineers and technicians create a strong, stable, and safe structure.